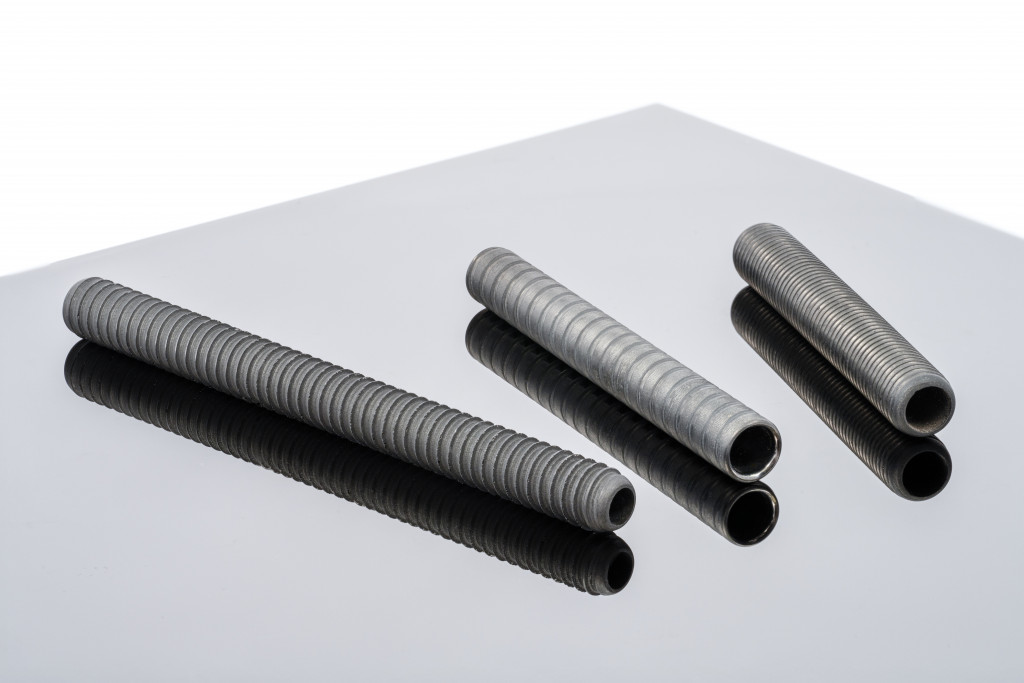

High Temperature Applications

Due to its high temperature resistance of up to 3000 °C SIGRADUR® glassy carbon is suitable for a wide range of high temperature applications. It is often used as a crucible material or for structural parts of high temperature furnaces but also as a material for pyrometer protection tubes and for construction of charging systems. Compared to ceramic and metallic materials, SIGRADUR® glassy carbon shows no embrittlement even at high temperatures and has an extreme resistance to thermal shock, allowing for very fast heating and cooling cycles. Further advantages are its low mass, low heat absorption and low thermal expansion.

Chemical and Analytical Applications

SIGRADUR® glassy carbon offers a high corrosion resistance which makes it an ideal material for various chemical applications and trace analysis. Compared to conventional laboratory equipment fabricated from platinum, gold, other corrosion resistant metals or special ceramics and fluoric plastics, SIGRADUR® glassy carbon shows (i) extreme resistance against all wet decomposition agents, (ii) no memory effect (i.e. uncontrolled adsorption and desorption of elements), (iii) no contamination of the analytical sample, (iv) strong resistance against acid and alkaline melts and (v) a non-porous, glassy surface.

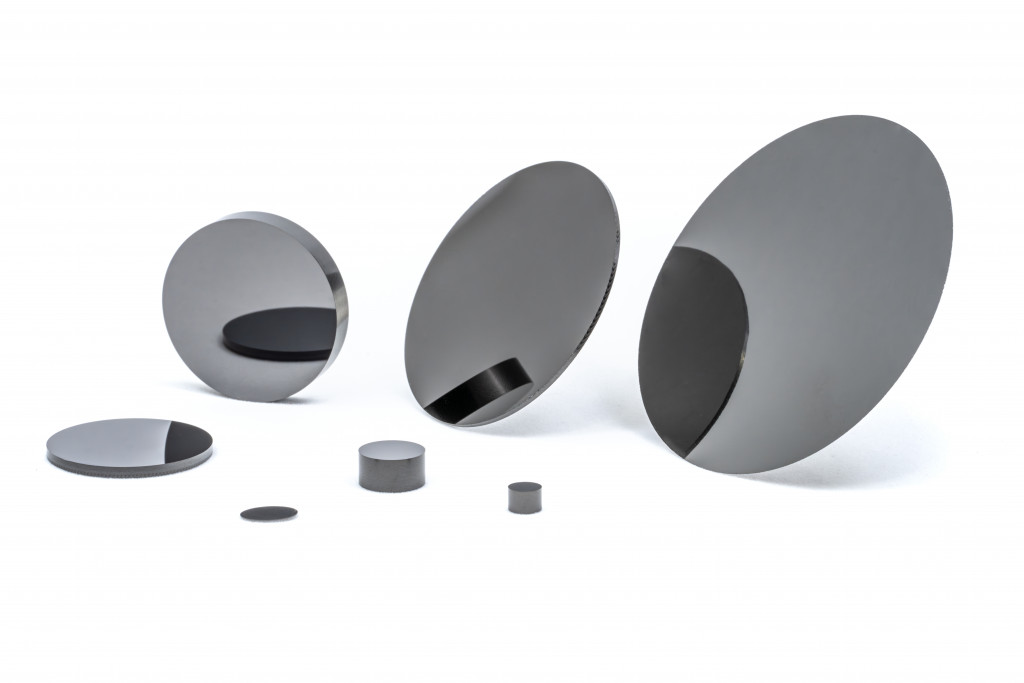

Electrochemical Applications

SIGRADUR® glassy carbon is an ideal electrode material as it shows a favorable redox response to the analyte, fast and reversible electron transport with no electrode fouling, a relatively wide window of cathodic potentials at which the electrode can perform and ease of surface cleaning in-between measurements. Combined with its low chemical reactivity, impermeability, high hardness and good electrical conductivity, SIGRADUR® glassy carbon has established itself over decades as a standard electrode material in the electrochemical industry. SIGRADUR® glassy carbon as an electrode also allows for electrochemical measurements at lower negative potentials than what can be generally achieved with Platinum or Gold. Compared to graphite electrodes, which exhibit a similar solid electrolyte interphase as that of SIGRADUR® glassy carbon, it is superior in terms of resisting the intercalation of foreign ions. Concrete use cases for SIGRADUR® glassy carbon electrodes include cyclic voltammetry, detectors in high pressure liquid chromatography or organic electro synthesis applications.

Metallurgical Applications

Melting crucibles made from SIGRADUR® glassy carbon are used in metallurgy and dental technology for melting precious metals and titanium or high-palladium alloys. SIGRADUR® glassy carbon crucibles show a demolding with a very high surface quality, no contamination by foreign elements and, owing to the hardness and wear resistance of the material, no carbon traces in the melting substance. Metal melts which do not form carbides have no wetting effect on SIGRADUR® glassy carbon which renders the use of melting salts obsolete. Its extreme thermal shock resistance allows for rapid heating and cooling times and red-hot crucibles do not crack when placed on cold surfaces. Also, owing to their good thermal conductivity, SIGRADUR® glassy carbon crucibles offer improved thermocouple readouts which allows the electric heating coil of the melting unit to be operated at lower temperatures compared to traditional ceramic vessels. SIGRADUR® glassy carbon crucibles can be used as susceptors in induction furnaces and are well suited for induction-heated casting centrifuges. In addition, SIGRADUR® glassy carbon crucibles generate a protective atmosphere over the metal during the melting process caused by a very low and consistent oxidation of the crucible material, which prevents the formation of an oxide layer on the molten metal. Furthermore, the metal-repellent properties of the crucible walls which obviate the necessity for melting salts or powders remain unchanged throughout the entire product life. SIGRADUR® glassy carbon crucibles are universally suited for melting all palladium-based alloys and alloys with a reduced precious metal content. They can furthermore be employed for melting palladium-containing fused ceramic alloys with reduced precious metal content at temperatures of up to 1400°C.

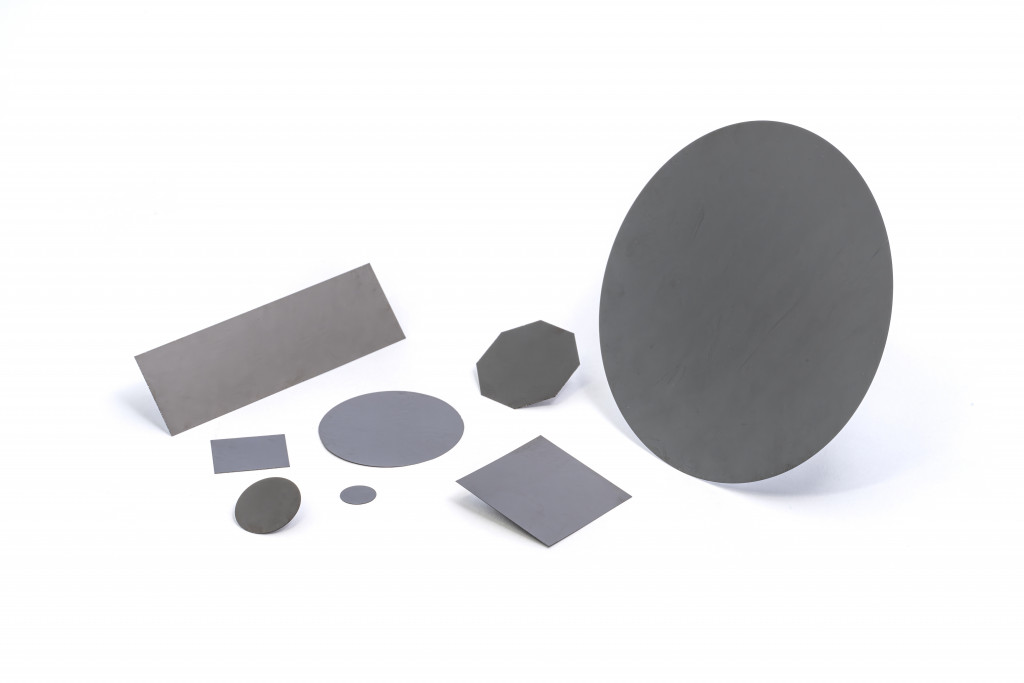

Semiconductor and Ultra-Pure Materials Applications

High purity, extreme corrosion resistance, no particle generation, good electrical conductivity as well as high hardness and strength render SIGRADUR® glassy carbon an ideal material for many applications in the semiconductor industry. Glassy carbon crucibles and boats are used for zone melting of semiconductor components, gallium arsenide synthesis and monocrystal growth by the Bridgman or Czochralsky method. Moreover, due to its extreme durability as an electrode material, SIGRADUR® glassy carbon is used for parts in plasma etching as well as ion implanting systems.

Biomedical Applications

SIGRADUR® glassy carbon shows an excellent biocompatibility with blood and tissue. Combined with good electrical conductivity, good mechanical properties, low density and high purity this renders SIGRADUR® glassy carbon an interesting material for various medical biotechnological applications. Use cases include electrodes for cardiac pacemakers, neural sensing and stimulation, cell culture substrates, three-dimensional scaffolding material or mechanical implants. Due to its high X-ray transmission rate SIGRADUR® glassy carbon also has various applications in medical radiotechnology.

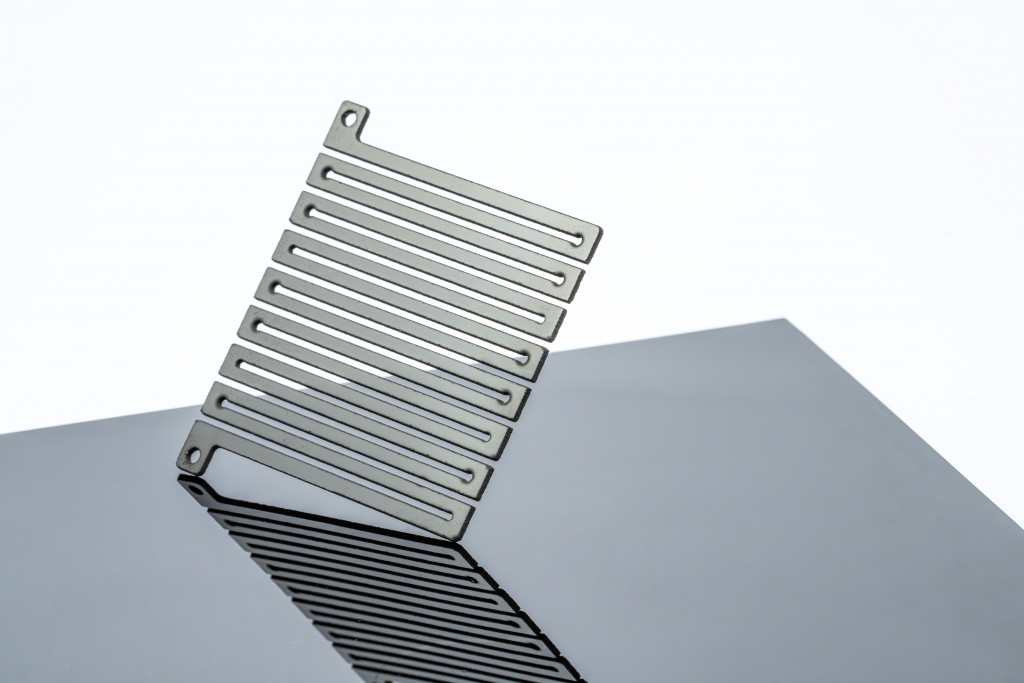

X-Ray Technology

Due to the relatively low atomic number of carbon, SIGRADUR® glassy carbon has a very low X-ray absorption rate. This is advantageous for many applications where X-ray transparency, impermeability and chemical inertness are of high importance. This is why SIGRADUR® glassy carbon is the material of choice for many X-ray window applications, as e.g. in synchrotron beamlines or X-ray imaging of high temperature furnaces and crystallization processes. Also many masking appliances for X-ray lithography.

Glass Industry

Due to its high temperature resistance, smooth surface, absence of particle generation, high hardness and strength as well as resistance to thermal shock SIGRADUR® glassy carbon is an ideal material for molding or melting glass components. As with molten metals SIGRADUR® glassy carbon does not show any wetting or wall adhesion with molten glass.