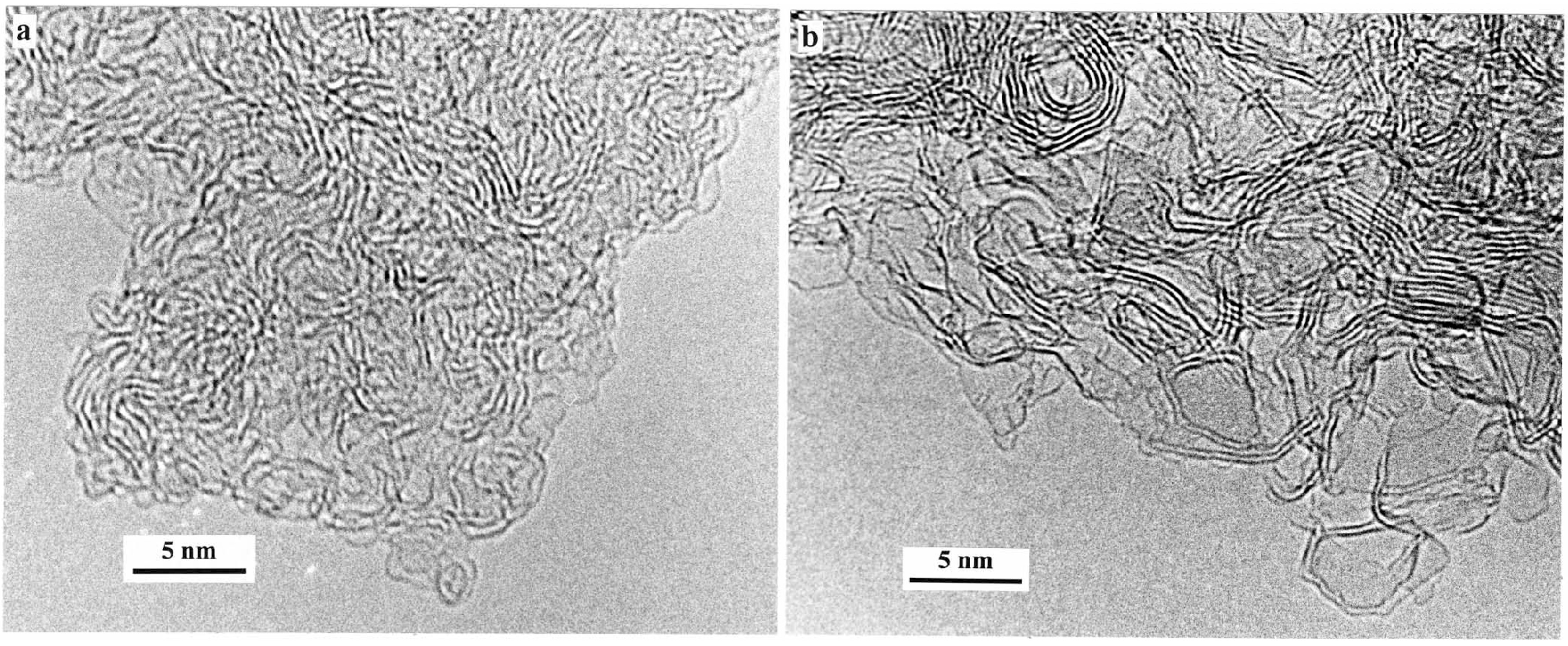

Glassy carbon, also known as vitreous carbon or glass-like carbon, is a non-graphitizing form of pure carbon that exhibits a unique combination of ceramic and graphite-like properties. While the exact microstructure of glassy carbon is still a topic of ongoing research it is commonly agreed upon that its basic building blocks consist of irregularly stacked and curved sheets of graphene. This mixture of ordered and amorphous microstructures leads to a variety of unique material properties.

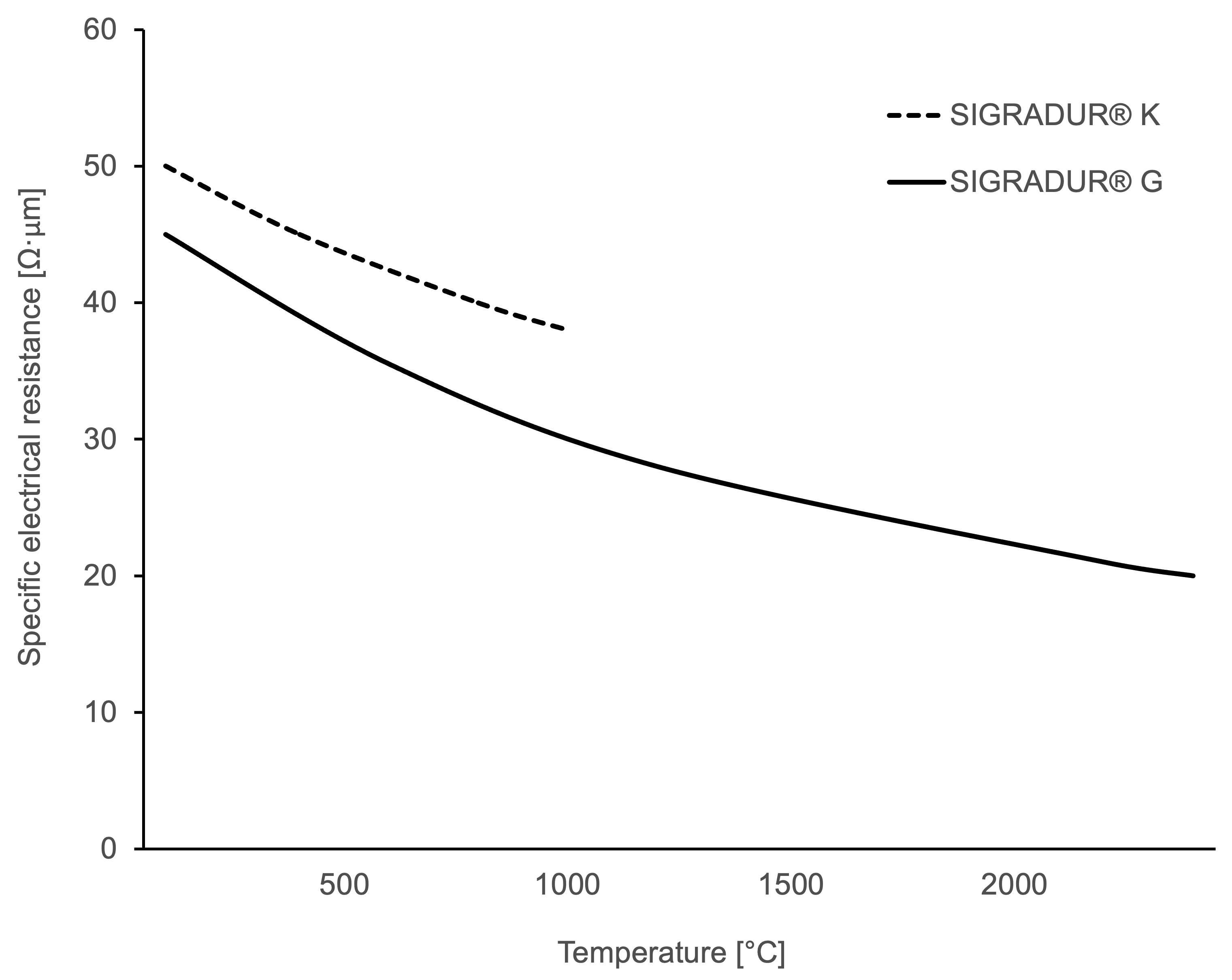

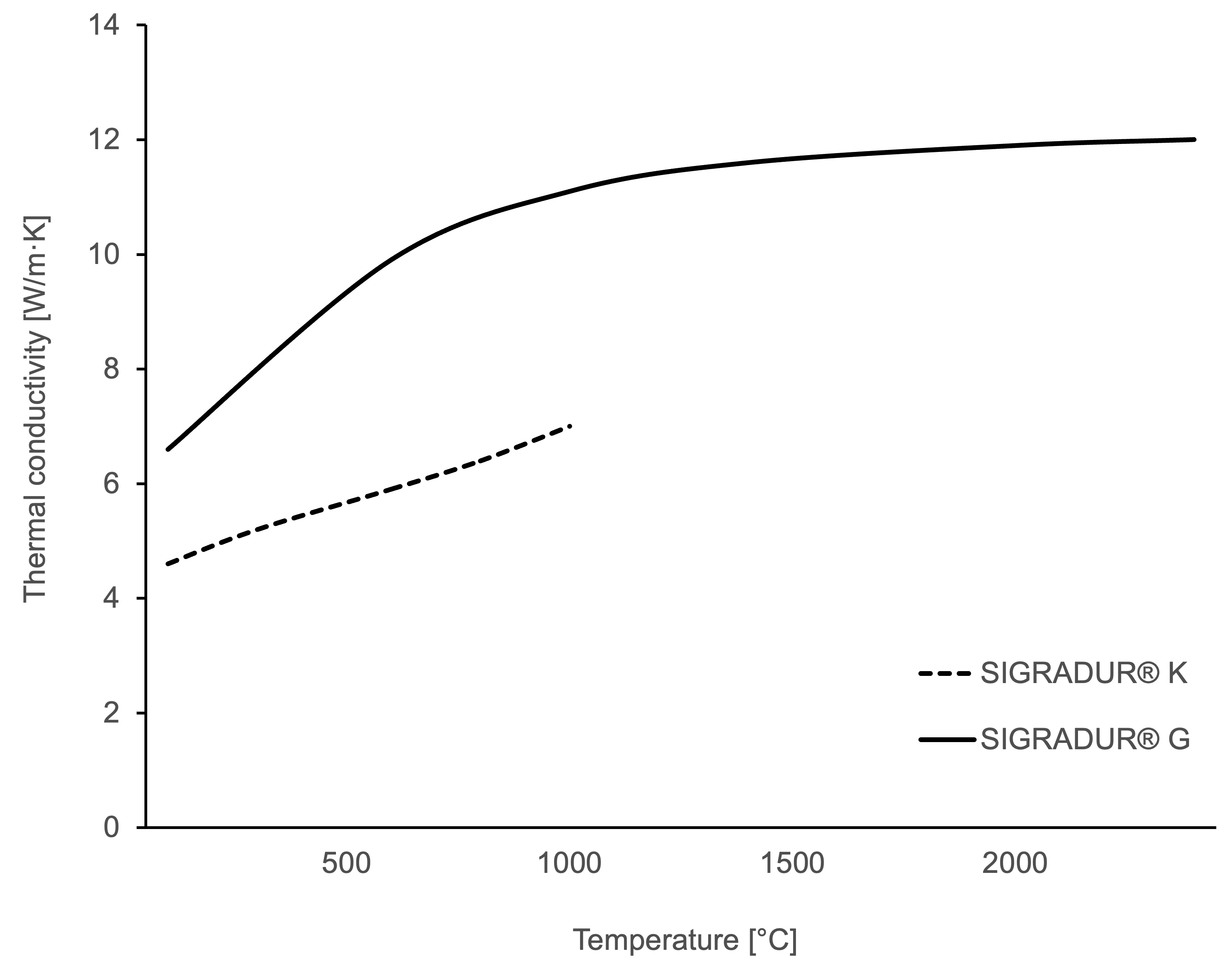

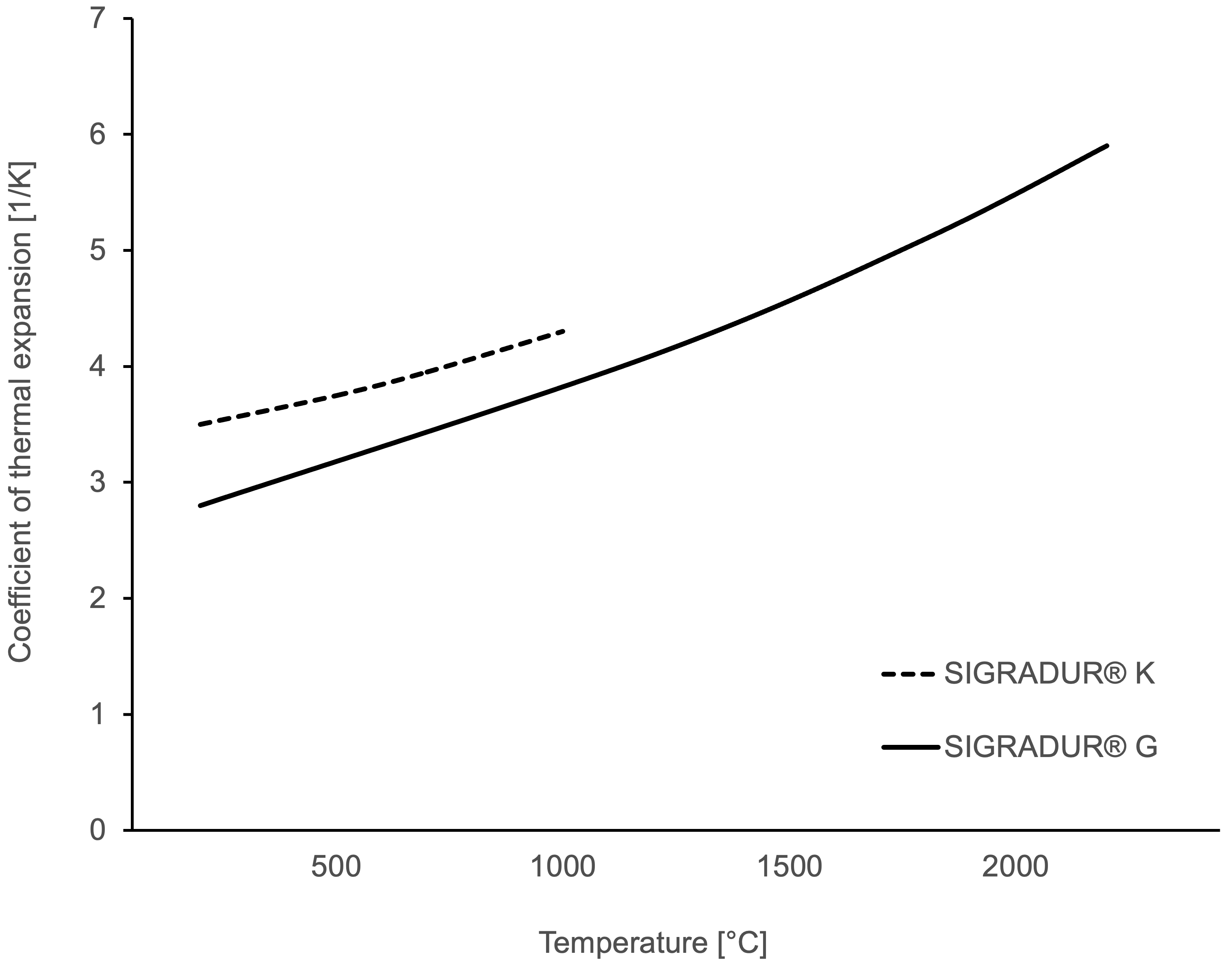

SIGRADUR® Glassy Carbon is an ultrapure form of glassy carbon heat treated up to 2200°C and is characterized by the following properties: